Heavy Duty Hose Pipe Fittings - Key Features to Look For

When you’re investing in heavy duty hose pipe fittings, you’re not just buying a connector, you’re specifying components that will stand up to demanding environments, high pressure and rigorous daily use. Whether you’re outfitting a construction site, industrial plant or utilities project, choosing fittings that deliver strength, reliability and longevity is essential.

In this guide, we’ll explain:

- What makes a hose fitting “heavy duty”.

- Key materials and construction features to prioritise.

- Practical examples from our range that fit the bill.

What Are Heavy Duty Hose Pipe Fittings?

“Heavy duty” hose fittings are engineered components designed to withstand greater stress, higher pressures and tougher environments than everyday domestic fittings. These are the connectors, couplings and adaptors used in sectors like construction, mining, manufacturing and emergency services where failure is not an option.

Heavy duty fittings typically have features like:

- Reinforced metal bodies (e.g., brass, galvanised steel, stainless steel).

- High-pressure sealing systems and internal reinforcements.

- Precision threads and standards-compliant coupling systems.

- Resistance to corrosion, wear and environmental hazards.

Key Features to Look For

#1: Robust Materials

One of the most important decisions when choosing heavy duty hose fittings is material choice. Different environments need different strengths:

- Brass and galvanised steel deliver excellent strength and corrosion resistance for construction and industrial environments.

- Stainless steel fittings are optimal for chemical, food processing and marine applications where corrosion resistance is critical.

- High-quality aluminium couplings are lightweight yet strong, frequently used in firefighting or water transfer applications.

IHP’s own fittings are manufactured with industrial-grade materials and in-house engineering expertise, giving you confidence in strength and durability.

#2: Built for High Pressure

For high pressure heavy duty hose fittings, it’s vital to choose connectors that can handle the force your system will generate.

- Look for pressure ratings backed by testing and compliance with recognised standards.

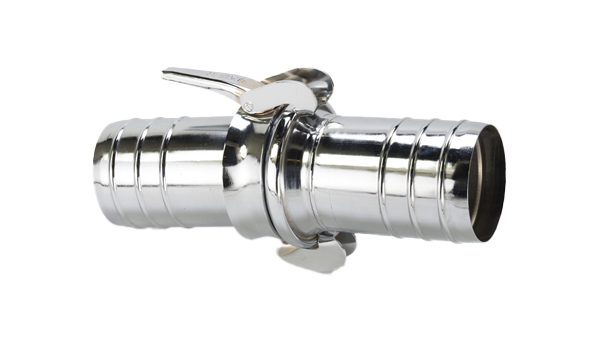

- Quick-connect systems are designed for fast, high-pressure water delivery, perfect for construction, dewatering, fire response and utilities. These IHP fittings conform to British Standard BS336 and are manufactured to withstand demanding use cases.

Quick-connect couplings allow for secure, leak-resistant connections even under intense flow and pressures, ideal when downtime isn’t acceptable.

#3: Seal Integrity and Leak Resistance

A heavy duty fitting is only as good as its seal. Poor sealing leads to leaks, pressure loss and premature wear.

- Choose fittings with quality gaskets or precision machined faces.

- Cam and groove style connectors, like camlock fittings, are highly popular for tough industrial duties, offering rapid assembly and strong sealing surfaces.

#4: Compatibility and Versatility

The best heavy duty hose fittings for construction or industrial use need to be versatile:

- Ensure fittings match the hose diameter and standard you’re using (e.g., BSP, NPT, Bauer, Storz).

- Keep modular systems in mind. Adaptors, reducers and multi-part couplings make it easier to integrate with pumps, valves and machinery.

For example, Bauer flange adaptors allow secure transitions between hose systems and mechanical interfaces in industrial setups.

#5: Ease of Installation and Maintenance

Heavy duty doesn’t mean complicated. Fast installation reduces downtime on site. Look for features like:

- Quick-release mechanisms

- Clear thread profiles

- Reusability without tools

Products like cam and groove fittings and quick connect couplings are designed with simplicity in mind, being both heavy duty and user friendly.

How to Choose Heavy Duty Hose Fittings

When deciding on fittings for your application:

High pressure applications like firefighting or dewatering need rated connectors that can handle the system conditions.

#2: Match materials to your environment

Corrosive or wet sites benefit from stainless steel, while general site use might be served with brass or galvanised steel.

#3: Check standards and compatibility

Align hose ends, threads and coupling standards across your system.

#4: Prioritise ease of use

Fast, reliable connections save time and reduce installation errors.

Durable Hose Fittings for Industrial Use

The right industrial hose fittings should offer:

- Long service life with minimal maintenance

- Resistance to impacts, abrasion and corrosion

- Compatibility with a broad range of hoses and fluids

From Bauer adaptors and quick connect coupling systems to heavy duty camlocks and bespoke engineered options, the IHP range covers a wide spectrum of industrial requirements backed by UK manufacturing expertise.

Investing in heavy duty hose pipe fittings pays dividends in reliability, safety and long-term performance. By focusing on material quality, pressure capability, seal, integrity and compatibility, you’ll be choosing the best heavy duty hose fittings for construction and industrial use, saving costly downtime and reducing maintenance headaches.

Ready to upgrade your hose infrastructure? Browse the IHP range or contact our expert team for tailored advice.

Proud to be a UK manufacturer

Proud to be a UK manufacturer